AI In Supply Chain Management: Its Impact & Benefits

- AI/ML

- September 13, 2024

AI in supply chain management is revolutionizing the way businesses optimize logistics, minimize costs, and boost efficiency. It leverages wider datasets, conducts predictive analytics and demand forecasting, enabling organizations to automate tasks and optimize inventory management. Besides, AI leads to better resource allocation and agility in the face of market changes. This blog discusses the role of Artificial Intelligence in supply chain management and how it benefits businesses.

Did you ever wonder how popular brands like Amazon, Walmart, Zara, and Unilever manage their broader supply chain? The answer is that they employ AI in the supply chain, catering to the needs of people from all walks of life.

Artificial intelligence (AI) in supply chain drastically revolutionizes everything from planning to production, along with management and optimization of all activities. Right from demand forecasting to procurement, inventory management, and logistics operations, it keeps every aspect of the supply chain balanced.

AI-powered systems process larger datasets, predict trends, customer behavior, and conduct demand forecasting for smart inventory management. This way, the system ensures appropriate availability of the product while circumventing overstocks and stockouts. Here’s all you should know about AI in supply chain management before getting in touch with an AI development company to implement it.

What Is AI In Supply Chain?

Artificial Intelligence (AI), in its broadest sense, is the intelligence exhibited by machines, especially computer systems that perform complex operations, simulating human intelligence. Businesses in the supply chain are leveraging this technology to manage and optimize numerous activities, including market analysis, demand forecasting, product quality monitoring, inventory level balancing, finding fuel-efficient delivery routes, and optimizing the entire supply chain management system.

Machine Learning (ML), a subset of AI, enables Artificial Intelligence to expand its intelligence by learning from a gigantic amount of data rather than being programmed by step-by-step instructions.

Thanks to this attribute of AI, it is capable of learning and can outclass traditional software solutions in many ways, like interpreting written and spoken texts, deciphering information from video feeds, and anticipating future market behavior. For example, an AI-powered supply chain system, using ML algorithms, can easily discover patterns within data sets that might be imperceptible to non-AI systems or human beings. It helps businesses make complex decisions by surfacing intense insights from large data sets.

What’s more, the AI-enabled supply chain solutions analyze weather and traffic conditions and recommend alternative routes for shipping, mitigating the risks of unexpected delays while maximizing the feasibility of timely delivery. Besides, AI can also keep track of workspaces and spot lower-quality control processes as well as health and safety violations.

How Does AI In Supply Chain Work?

Businesses make use of Ai in the supply chain to analyze data, make data-driven decisions, predict future demands, ensure efficient procurement, increase productivity, strengthen warehouse management, optimize distribution routes, and many more.

The supply chain, especially in the goods manufacturing industry, becomes complicated. This is because these companies mostly rely on several partners from different locations for the timely shipment of components to their assembly facilities. The use of AI efficiently finds patterns and relationships within large data sets, helping businesses to optimize the entire logistics network from cargo freighters to delivery trucks, warehouses, and distribution points.

Apart from that, supply chain optimization also needs efficient tracking of physical goods every single time they switch hands. Artificial Intelligence can be the right solution here, as it comes with competencies to accurately enter, extract, and classify data in text files, ensuring the integrity of multiparty transactions.

The new-era supply chains tend to be expansive and require comprehensive oversight to circumvent unnecessary disruptions and losses. Artificial Intelligence in supply chain management offers assistance like demand forecasting, planning production, and warehouse capabilities to ensure services that meet customer’s requirements.

Apart from these, there are companies out there making use of Artificial Intelligence to gain insights from a larger data set accumulated from Internet of Things (IoT) devices deployed across the supply chain.

AI in the supply chain ensures transparency for the manufacturers while offering invaluable insights for stakeholders. That level of transparency in the supply chain results in cutting a huge chunk of time and costs, ensuring the next level of business benefits.

AI Adoption Rate In Supply Chain: Stats & Facts

The following are some of the key statistics, indicating the uses and adoption of Artificial Intelligence in supply chain management:

- The supply chain marketplace is anticipated to exhibit a CAGR of 8.60% between the years 2022 to 2029.

- Around 70% of supply chain professionals use AI, seeking opportunities to cut down on operational costs.

- AI-powered predictive maintenance optimizes equipment performance, lessening the maintenance cost by up to 15% to 20%.

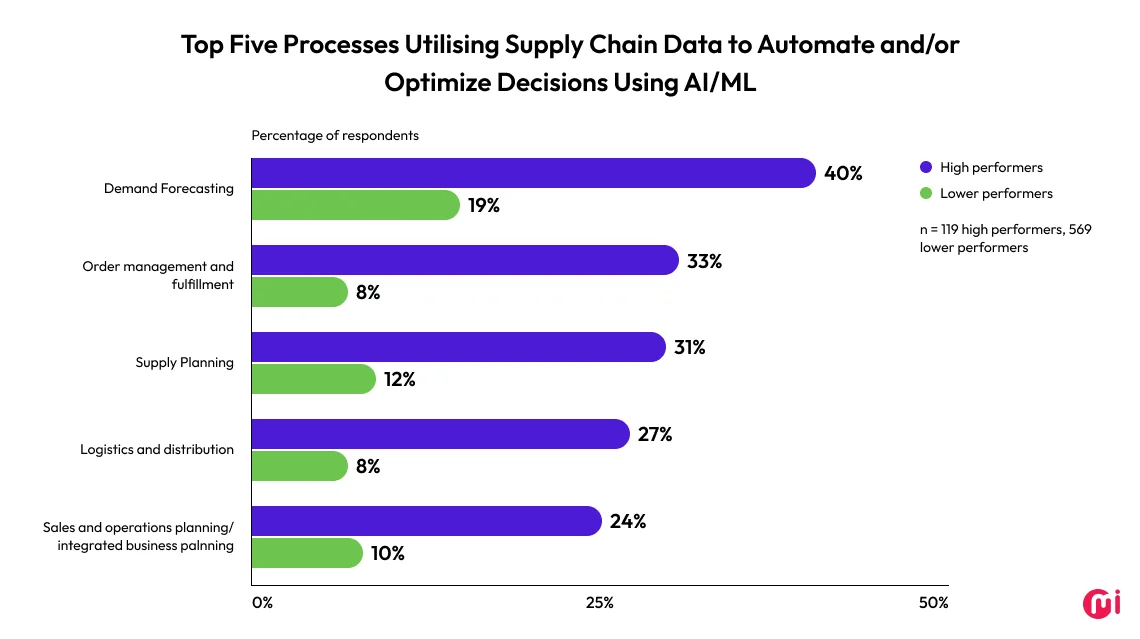

According to stats from Gartner, businesses using AI supply chain management solutions are more likely to be high performers compared to those missing out on using the same. Have a glance at the image below!

The image above shows how those who implemented AI-powered solutions became the high performers compared to those who didn’t do that. Whether it’s demand forecasting, order management, and fulfillment, supply chain planning, logistics & distribution, or something else, using AI-enabled systems helps businesses get ahead of the curve. For more, you can refer to our recently published guide on how AI in manufacturing is redefining the industry.

Key Areas for Implementing AI in Supply Chain Management

Artificial Intelligence in supply chain enables better forecasting, inventory management, and logistics optimization, improving overall supply chain management and performance. Mentioned below are the key areas of the supply chain where you can implement AI to improve the way it functions:

1. Demand Forecasting

AI algorithms perform demand forecasting by analyzing historical data, real-time market trends, and many other factors such as economic outlooks. Machine learning, a subset of AI, learns from historical and new data and forecasts demand, enabling companies to adjust their inventory levels accordingly. This helps businesses ensure an appropriate inventory level in the warehouse, limiting overstocks and stockouts.

2. Inventory Management

AI in inventory management optimizes stock levels, warehouse layouts, and reorder points, minimizing holding costs and maximizing inventory turnover. AI-based supply chain predicts the time when product demand will rise and automates inventory tracking and management. The system analyzes demand patterns, ensures the inventory is appropriately managed, alleviates the carrying cost, and expands the service levels.

3. Logistics Optimization

AI in supply chain is used to optimize warehouse capacity, shipping routes, and delivery times, leading to faster delivery, reduced transportation costs, optimized logistics, and enriched customer satisfaction. AI applications plan appropriate delivery routes, conduct load management, and scheduling to improve overall logistics efficiency.

4. Predictive Maintenance

AI efficiently analyzes sensor data collected from machinery and equipment to predict potential breakdowns and schedule maintenance proactively. Predictive maintenance by AI and IoT takes a smarter approach by using real-time data like vibration, temperature, pressure, noise, etc., from sensors to anticipate failures before they take place. It helps minimize downtime and production losses.

5. Supplier Relationship Management

Artificial Intelligence in supply chain management helps businesses identify reliable suppliers, monitor supplier performance, and streamline procurement processes. It does so using data analytics, machine learning, and automation.

AI analyzes massive datasets to evaluate and rank suppliers according to factors like historical performance, financial stability, reputation analysis, and risk exposure. Some examples of AI-driven supplier management solutions are Ivalua, SynerTrade, GEP SMART, etc

6. Anomaly Detection

AI algorithms identify and flag anomalies in the supply chain, like discrepancies, delays, or unusual patterns, to prevent potential disruptions. In complex supply chains, disruptions often start small. It might be a late shipment, a data entry error, or an unusual inventory level. AI-powered anomaly detection ensures organizations spot these early warning signs before they escalate into expensive delays or losses.

7. Automation with Gen AI

GenAI can automate tasks, such as documentation, help with training, and optimize logistics, leading to streamlined efficiency and reduced costs. Supply chain operations involve large volumes of paperwork, like invoices, bills of lading, customs declarations, compliance reports, etc.

GenAI automates these processes by generating standard documents, extracting and entering data, and more. This leads to faster operations, lower costs, and better resource utilization.

Benefits of AI in Supply Chain Management

Implementing AI in supply chain management brings along a wide array of benefits, including enhanced visibility, increased efficiency, improved forecasting, reduced costs, and better risk management. It helps businesses gain invaluable insights, automate tasks, optimize processes, making the supply chain flawless and beneficial. Here are all the benefits you should be aware of:

1. Enhanced Visibility

Using technologies like IoT sensors, machine learning, and real-time analytics, AI provides real-time visibility into the supply chain, enabling better decision-making and quicker responses to changes. Artificial Intelligence integrates data from ERP systems, IoT devices, and logistics platforms to ensure end-to-end visibility.

Machine learning algorithms assess this real-time data, enabling them to track inventory, shipment, and vendor performance in real-time.

2. Increased Efficiency

AI employs technologies like Robotic Process Automation (RPA) and Predictive Analytics, allowing it to automate repetitive operations such as demand forecasting, purchase order creation, invoice matching, and many more. It speeds up workflows and reduces human error, ensuring efficiency throughout the supply chain.

3. Real-time Decision Making

AI in supply chain provides predictive analysis and real-time insights, empowering businesses to make informed decisions quickly and effectively. AI-powered supply chain management uses technologies like AI Dashboards, Stream Analytics, and Edge Computing, enabling real-time visibility, proactive risk identification, and optimized decision-making.

The system processes live data to provide actionable insights instantly. For instance, route optimization and dynamic pricing engines react in real time to any change in supply and demand, fostering real-time, more efficient decision making.

4. Improved Resilience

Using technologies like Predictive Modeling, Risk Analytics, and Digital Twins, AI-powered supply chain management ensures improved resilience throughout the supply chain. The system simulates supply chain scenarios using digital twins and identifies vulnerabilities leveraging predictive models.

It enables businesses to prepare for disruptions, like supplier shutdowns or natural disasters, to deal with any circumstance.

5. Smart Procurement

Artificial Intelligence, making technologies like Natural Language Processing (NLP), and ML-based Supplier Scoring, fosters smart procurement. AI-powered systems analyze contracts and emails using NLP and ascertain the right rate for suppliers based on delivery history, price trends, and compliance, ensuring accurate and streamlined procurement.

AI in inventory management allows professionals to optimize inventory levels and circumvent overstocks and stockouts, keeping the business ready around the clock, all year round.

6. Mitigated Errors & Waste

Using technologies like Machine Learning, Automation, and Anomaly Detection, AI in supply chain management reduces errors and waste. ML models detect unusual consumption patterns or transactional errors, while automation minimizes mistakes made by humans in inventory, invoicing, and production scheduling.

Machine learning, automation, and anomaly detection work hand in hand and reduce errors and waste by identifying anomalies early, preventing defects, and boosting process efficiency. Machine learning empowered automated systems to find and fix errors, while anomaly detection pinpoints deviations from expected behavior, helping avoid issues before they escalate.

7. Transportation Optimization

AI in supply chain optimizes transportation routes, efficiently manages logistics operations, and improves delivery schedules, resulting in increased efficiency and reduced costs. Technologies like Geospatial Analytics, Route Optimization Algorithms, and AI Telematics allow analyzing real-time traffic, weather, and shipment data, optimizing delivery routes, reducing fuel use, and improving punctuality throughout intelligent dispatch systems.

8. Warehouse Automation

AI in supply chain management makes use of technologies like Computer Vision, Robotics, and AI-Powered WMS (Warehouse Management Systems), ensuring efficient warehouse automation. Autonomous robots and vision-guided systems assist scanning, sorting, and packing while AI-driven WMS ensures optimal inventory layout and space utilization.

What’s more, they optimize the store locations within the warehouses according to demand patterns, which helps improve retrieval times.

9. Accurate Inventory Management

AI tracks real-time inventory levels and identifies optimal restocking points, leading to improved inventory turnover and reduced storage costs. Using Demand Forecasting Algorithms, IoT, and Machine Learning, AI models predict inventory needs based on historical trends, seasonal patterns, and market behavior, while IoT devices provide real-time stock updates.

Leveraging the power of technology, AI ensures accurate inventory management, eliminating the chances of stockouts while optimizing opportunities for benefits.

10. Better Sustainability

AI helps businesses to optimize transportation routes, reduce waste, and identify opportunities for sustainable sourcing, ensuring an excellent supply chain. Using carbon tracking AI, supply chain mapping tools, and optimization algorithms, AI helps organizations to monitor environmental KPIs, limit packaging waste, optimize routes to cut emissions, and keep track of suppliers’ sustainability metrics.

It helps ensure enhanced business sustainability, contributing to elevating business profitability.

11. Proactive Risk Management

AI in supply chain identifies potential disruptions by analyzing various data sources, including market conditions, geographical events, and weather patterns, enabling proactive risk management strategies. With technologies such as AI Risk Engines, Big Data Analytics, and Scenario Simulation, AI evaluates data from markets, suppliers, and geopolitical sources.

This data evaluation helps to identify risks and recommend mitigation strategies before they cause to impact operations. AI-enabled inventory management systems also assist you in fraud detection by identifying unusual behaviors and patterns and preventing any possibility of potential risks.

12. Seamless Collaboration

Artificial Intelligence makes use of technologies like Cloud-Based AI Platforms, API Integration, and NLPs, ensuring seamless collaboration throughout the supply chain. AI ensures unified communication between different departments and partners via shared dashboards, smart alerts, and voice/email processing tools.

By providing real-time data insights to the stakeholders, such as the warehouse manager and logistics manager, it ensures seamless collaboration across departments, fostering flawless supply chain management.

13. Efficient Customer Service

Using technologies like AI Chatbots, Sentiment Analysis, and CRM Integration, AI-powered supply chain management reduces disruptions, improves efficiency, and ensures timely deliveries. NLP-driven chatbots efficiently troubleshoot queries instantly, while AI tools analyze customer feedback and anticipate concerns before they escalate.

Through all these processes, AI-powered supply chain enhances customer satisfaction, elevating business profitability in the long run.

14. On-Time Delivery

Using technologies like AI-Driven Scheduling, Real-Time GPS, and Predictive ETA Tools, AI-powered supply chain promotes timely delivery. AI predicts accurate delivery times, monitors shipment locations, and proactively re-routes deliveries, making sure fulfillment gets done on time.

Besides, it prioritizes shipments based on order volumes, delivery promises, contractual deadlines, customer importance, or product availability. They also provide all nodes throughout the distribution network with accurate time of arrival by shipment identification.

15. Reduced Operational Costs

AI in supply chain optimizes operations, reduces waste, and improves efficiency, hence significantly lowering operational costs. Employing technologies like Automation, Optimization Engines, and AI Cost Analysis Tools, AI cuts down manual workload, prevents overstocking, minimizes returns, and provides insights into the areas where costs are likely to be trimmed throughout the supply chain.

Moreover, an AI-powered supply chain system limits repetitive tasks like tracking, counting, and documenting inventory with optimized efficiency and accuracy. It reduces the performance bottleneck by identifying and lessening it, thereby reducing the overall operational costs.

Real-Life Examples of AI In Supply Chain Management

From Amazon to Walmart, and IBM and Maersk to Dell, businesses are frequently using AI for supply chain optimization. Look at the AI in supply chain examples and how they are impacting business operations:

1. Amazon

Amazon experienced a 75% increase in speed after AI implementation in its supply chain. The retail giant invested in a new robotic inventory management system called “Sequoia”, which helps pinpoint and store inventory 75% faster. It helps Amazon lessen human efforts and employee injury by 15%, and cut down the processing time by 25%.

Role of AI: To optimize what, where, and how much inventory is needed across networks.

How It Works: AI models conduct demand forecasting based on region and determine optimal warehouse stocking.

Additional Tools: Computer vision and Robotics assist with stock counts and picking.

Impact: Minimizes overstocking and stockouts, and reduces shipping time and costs.

2. Walmart

Walmart has developed an AI-driven Route Optimization system, allowing it to streamline its logistics while reducing environmental impact. It helps optimize driving routes, pack trailers efficiently, and minimize miles traveled. The system helped Walmart avoid 94 million pounds of CO² by eliminating 30 million needless miles driven and optimizing routes to bypass 110,000 inefficient paths.

Role of AI: To optimize delivery logistics and minimize miles driven, fuel usage, and emissions.

How It Works: AI processes real-time data (weather, traffic, order volumes) to generate multi-stop delivery routes along with backhaul inventory pick-up plans.

Additional Tools: Integrated with warehouse packing algorithms and logistics orchestration systems, aiming for full-stack fulfillment optimization.

Impact: Eliminated 30 million unnecessary miles, 94 million pounds of CO₂ emissions while skyrocketing fleet productivity.

3. Zara (Inditex)

Zara employs Artificial Intelligence in supply chain management for demand forecasting. It analyzes sales trends, market conditions, and external events, enabling the company to adjust production and inventory levels, bringing supply in alignment with customer demand.

AI Role: To predict customer demand, customize product offerings, and automate restocking.

How It Works: AI assesses social media trends, POS (point of sale) data, and customer feedback to adjust inventory and styles.

Rapid Response: Zara uses AI and speeds up the production and delivery of trending items.

Impact: Shortens product cycles, limits unsold stock, and aligns supply closely with demand.

4. IBM

IBM’s Sterling Supply Chain Control Tower is designed to provide real-time visibility across the supply chain. Backed by AI, it predicts potential disruptions and provides actionable insights, allowing organizations to respond proactively to changes.

AI Role: Real-time monitoring, forecasting, and exception handling throughout the supply chain.

How It Works: AI monitors data from manufacturers, suppliers, logistics partners, and markets, ensuring comprehensive visibility.

Real-Time Decisions: It predicts shipment delays, suggests alternative routes or suppliers.

Impact: Elevates supply chain agility, lessens response times to disruptions, such as supplier shutdowns and natural disasters.

5. Unilever

Unilever employs an AI-enabled system, Scoutbee, to assess supplier risks by analyzing larger data sources. These diversified data might involve market trends and financial reports. This proactive approach helps Unilever make informed decisions and minimize potential disruptions.

AI Role: To evaluate, monitor, and predict supplier performance and risks.

How It Works: AI analyzes structured (financial data) and unstructured data (news, ESG reports) about its suppliers.

Why It Matters: It enables Unilever to predict disruptions (political instability or environmental risks), assess compliance, and ensure ethical sourcing.

Impact: Creates a more resilient and transparent supplier network, eliminating the risk of supply chain shocks.

Challenges of AI in Supply Chain with Their Solutions

AI implementation in supply chains comes across challenges like integration issues with existing systems, poor data quality, high costs, and resistance to change. The solutions should involve investing in scalable AI platforms, focusing on data quality, and addressing ethical concerns and biases. Here’s a detailed answer to this question:

1. Infrastructure & Technology

Integrating Artificial Intelligence in the supply chain may encounter issues with technology and infrastructure. Inadequate infrastructure and incompatible platforms may cause obstacles when integration.

Solution: Upgrade the existing infrastructure and prefer implementing cloud-enabled solutions for scalability. Contact a cloud engineering service company for smooth integration.

2. Data Quality & Availability

The AI algorithms need high-quality data to work properly and produce findings. At times, it could be difficult to efficiently implement AI mode if the supply chain data is inconsistent, incomplete, or of low quality.

Solution: Consider data cleaning and validation procedures. Employ data governance procedures to ensure data accuracy and consistency.

3. Integration with Existing Systems

AI solutions may not always readily integrate with legacy systems, causing interoperability issues

Solution: Consider adopting middleware or API-based solutions, and start with pilot projects and scale gradually to bridge legacy systems with AI tools.

4. High Implementation Costs

The initial investment in AI implementation in the supply chain might be capital-intensive.

Solution: Use AI-as-a-Service (AIaaS) or cloud-based platforms. Employ open-source tools and pre-trained models to minimize upfront infrastructure costs.

5. Lack of Skilled Talents

Finding experts excelling at AI and supply chain management can be difficult.

Solution: Upskill existing employees with AI and data literacy training programs, or you can hire AI developers from a reliable service provider.

6. Ethical Concerns and Bias

AI models may be biased, leading to discriminatory outcomes.

Solution: Consider implementing ethical AI frameworks and conducting bias audits on models. Deploy diverse data sources and teams for model development.

7. Resistance to Change

Some employees may resist adopting new AI tools and processes.

Solution: Communicate AI’s role as a decision support tool, involve end users early in the design and deployment process, and showcase quick wins through pilots for trust building and value demonstration.

8. Security & Privacy

Since AI processes a wide range of data, protecting sensitive data from breaches is a major concern.

Solution: Implement robust encryption, data anonymization, and access control practices. Consider ensuring compliance with regulations like GDPR and CCPA. Besides, consistently audit AI systems and data flows for vulnerabilities.

9. Complexity and Scale

Integrating AI in supply chain management can be complex, needing careful planning and implementation to manage its scale.

Solution: Make use of scalable, cloud-native AI platforms with a distributed architecture. Get started with high-impact nodes in the supply chain and expand gradually.

The Future of AI in Supply Chain Management

AI is transforming the logistics and supply chain industry to a massive extent. A considerable part of this is that it’s just the beginning, and AI will have a great impact on supply chain management. Here are some predictions on the future of AI in the supply chain!

- By analyzing large amounts of historical data, AI will provide predictive analytics, allowing companies to accurately forecast future demands and optimize inventory levels to enhance business efficiency.

- AI will be analyzing data from machinery and equipment to circumvent failures before they occur, ensuring predictive maintenance and accuracy.

- AI-enabled robotics will be impacting warehouses by boosting productivity and reducing costs.

- With enhanced security measures and faster deliveries, autonomous vehicles will be taking logistics and supply chains to the next level.

How to Implement AI in Your Supply Chain

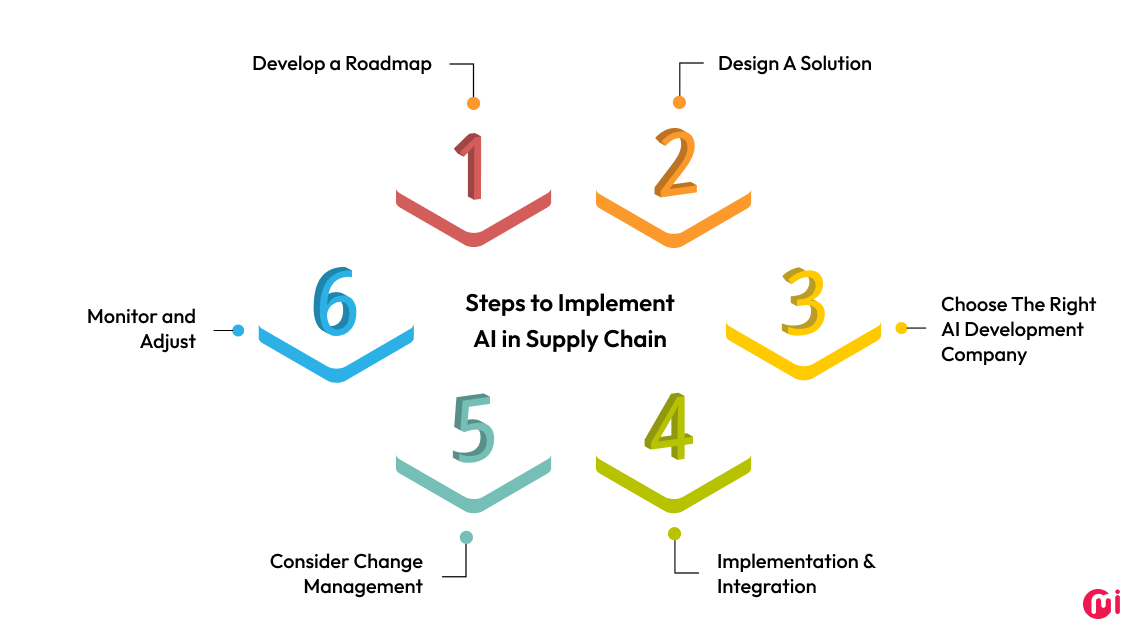

Many businesses may find it challenging and expensive enough to get AI to run completely in their production environments. The following are the key steps that you can take to get your supply chain ready for AI implementation with ease and convenience:

1. Develop a Roadmap

Supply chain modernization involves many problems to resolve and benefits to leverage. Develop a roadmap and make sure each stage enables the next to have adequate funding. Decide on the priorities before you outline the specific project, and then come up with a strategy that’s capable enough to address the most pressing concerns in the initial phases.

2. Design A Solution

Identify the specific areas of supply chain operation with the potential to bring optimal benefits by AI infusion and get the solutions designed appropriately. Determine the type of solution needed, like cloud-enabled apps, data science platforms, edge servers, and internet-connected devices and sensors. Also, ascertain how they are required to integrate with each other and your existing resources.

3. Choose The Right AI Development Company

The selection of a service provider is essential when it comes to nurturing a long-term relationship. Consider performing a careful assessment of the competencies of each bidder. It may involve assessing their technical capabilities, support models, price, and the like.

4. Implementation & Integration

Once done with the vendor selection, begin with the implementation and integration process. The implementation phase needs some downtime and employs training once it is done. If you perform effective execution, the switch from staging to production is more likely to be completed with minimal effort.

5. Consider Change Management

Before you implement a new Artificial Intelligence powered solution, develop a strategy to prepare the entire workforce to adopt it. Create a change management plan which includes communicating with coworkers regarding the issues and aims for which the AI integration has taken place. Besides, let them know the productivity the organization intends to obtain and the benchmarks leaders are expected to use to evaluate project success.

6. Monitor and Adjust

AI tends to be a dynamic technology that keeps on evolving through a feedback loop of monitoring and adjustment. Even when AI-powered systems seem to be working properly, you should experiment with modifications and accumulate data capable of tracking results, intending to indicate further performance refinements.

Level-Up Your Supply Chain with MindInventory

MindInventory is a leading AI/ML development company, providing businesses with a suite of AI ML development services to meet their needs. Be it AI development, ML development solutions, Generative AI development solutions, or Data Science solutions, we excel at delivering comprehensive solutions that meet your expectations.

Leveraging our years of experience, we have developed a supply chain solution for Panasonic that is helping them optimize operations. With this solution, the client experienced a 20% reduction in inventory discrepancies, an increase in warehouse productivity by 25%, 15% cost savings through optimized space and efficiency, and a great deal of profitability in the business.

Be it AI consulting, design, or development, we provide businesses with the solution they need to manage their business efficiently. So, if you’re willing to get your supply chain enabled with AI, get in touch with us, and we’ll help you get there with ease. Share your project requirements and let your business be a go-getter!

FAQs On AI in Supply Chain

According to research from Grand View Research, the global artificial intelligence market is predicted to reach $1,811.75 between 2025 to 2030 at a compound annual growth rate (CAGR) of 35.9%. This report shows the significance of AI in the marketplace.

AI makes use of predictive models to forecast future demand based on real-time and historical data. ML algorithms are at the core of AI-enabled demand forecasting systems. These algorithms employ a wide range of data, including historical sales, customer preferences, behavior, and current trends, intending to pinpoint patterns and make predictions for future demands.

AI in supply chain forecasts demand by leveraging machine learning and big data analytics to analyze present as well as historical data, identify patterns and trends, and predict future demands. It helps businesses to optimize inventory levels, reduce waste, and circumvent overstocks and stockouts.

AI can enhance supply chain sustainability by reducing waste, improving efficiency, and promoting transparency. Artificial intelligence in supply chain management optimizes various aspects from demand forecasting and inventory management to transportation and resource allocation, leading to lower environmental impact and increased operational efficiency.